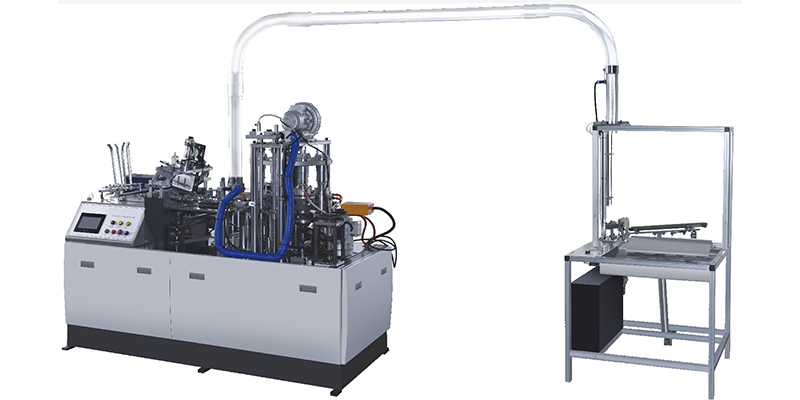

FBN-588 ULTRASONIC AUTOMATIC PAPER CUP MAKING MACHINE DESCRIPTION :

FBN-588 with advanced design and intelligent program ,more reliable and durable .competitive price .it make both one side or two side PE film coated paper cups after running a whole procedure of automatic multi-step pre-printed cup fan paper feeding (multi-step paper feed and anti-back device to keep the accurate position)cup-body-side welding silicone-oil lubrication(for top curling).robot transfer cup body.bottom-disk punching .bottom pre-heating and pre-folding.main heating bottom knurling(cool device for 2PE) top curling,cup discharging and collecting .

FBN-588 ULTRASONIC AUTOMATIC PAPER CUP MAKING MACHINE TECHNICAL SPECIFICATION

|

Suitable cup size |

40ml-16oz |

|

Speed of machine |

70-90pcs/min |

|

Suitable Material of paper |

150-350gsm with PE single PE face or double PE coated paper |

|

Power required |

380v 50hz 3phase or customized Different power should be noticed before order machine |

|

Total power |

4.5kw |

|

Weight of machine |

1750kg |

|

Size of machine |

2000X1230X1700mm |

|

Working pressure |

0.4MPA |

|

Air required |

0.6M3/MIN (need buy air compressor extra) |

|

Paper cup making machine can be customized according to different paper cup . |

|

FBN-588 ULTRASONIC AUTOMATIC PAPER CUP MAKING MACHINE ELECTRONIC LIST

|

NAME AND MODEL |

QUANTITY |

BRAND NAME |

|

PLC |

1 |

Delta TaiWan |

|

Touch screen |

1 |

Delta TaiWan |

|

Variable-frequency driver |

1 |

Delta TaiWan |

|

Power switch |

1 |

Delta TaiWan |

|

Ultrasonic |

1 |

kejian |

|

Encoder |

1 |

Omron Japan |

|

Sensor Panasonic |

1 |

Panasonic Japan |

|

Contactor (LC1E0901) |

1 |

Schneider France |

|

Contactor (1210) |

2 |

Schneider France |

|

Contactor (3210) |

1 |

Schneider France |

|

Relay |

11 |

Schneider France |

|

Air switch (3P-D63A) |

1 |

LS Korea |

FBN-588 ULTRASONIC AUTOMATIC PAPER CUP MAKING MACHINE IMPROVEMENT

1.HMI&PLC program control,easy operate and intelligent .

2.Sensor detects all running steps ,fault guide ,keep good quality paper cups and machine long life.

3.Stable speed 70-80pcs/min(machine can running by speed 100pcs/min some times,but it is no good for machine running long time by so high speed )

4.Step motor control the bottom feed.precision and reliable .one cup fan cut one bottom disc .no wastage.

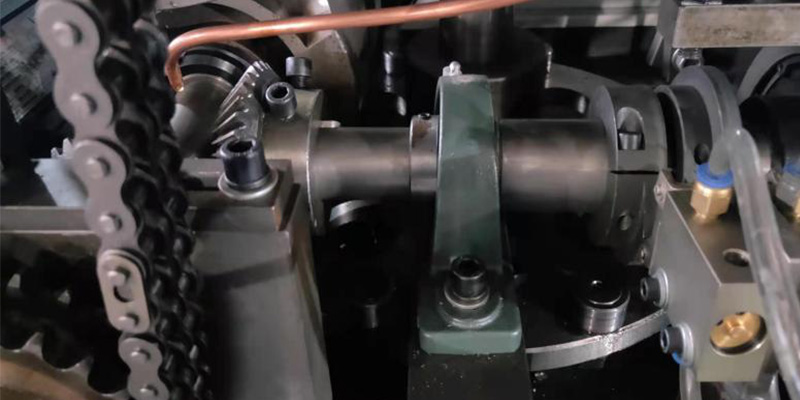

5.Good quality open cam(8 divide) drive easy maintenance .stable and reliable .remote controller .easy control and adjustment .

6.Separate cam &rod driver the knurling .curling and heating parts .to keep machine stable and easy maintenance .

7.Quality electric elements.long life (Delta Schneider,famous brand name )

Separately cam &rod .driver the knurling.curling and heating parts .to keep machine stable and easy maintenance

8.working power only 4.5kw .save cost(no include the air compressor )

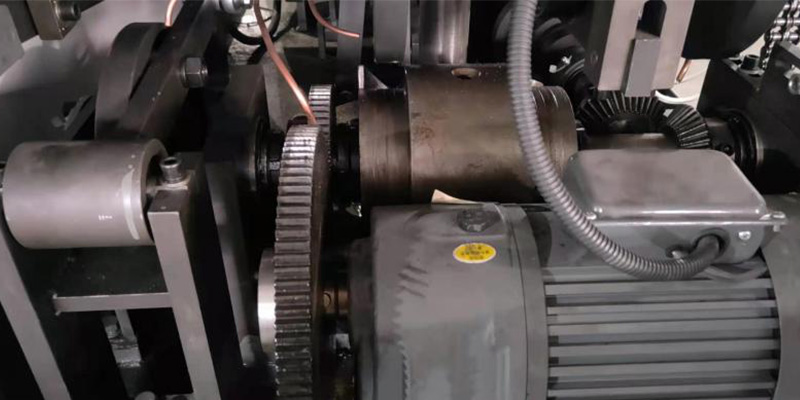

Only one main turntable .more efficient and reliable

Self lubricate (automatic oli lubricate )

Robot straight lift the cup body to main mold

Body dish straight punched and send to the cup body ,less wastage and precision

Advanced bottom knurling system .reliable and long life

Cup side sealing by ultrasonic