PRODUCTS

TECHNICAL SPECIFICATION

|

Model |

FBN-HC600 |

|

Paper cups specification |

4-14oz (100-450ml)(mold exchangeable) T:55-85mm H:60-135mm B:55-70mm |

|

Air supply requirement |

0.5-0.8MPa,0.4cbm/min |

|

Paper specification |

150-350 GSM single/double PE coated paper |

|

Production capacity |

60-85 pcs/min(for handle max is 70pcs/min) |

|

Voltage |

220V/380V |

|

Total Power |

7KW |

|

Total Weight |

3000KG |

|

Dimensions |

2800mm*1300mm*1850mm |

|

Note |

Customized service is available |

MAIN PARTS BRAND

|

Item |

Brand |

Original |

|

Main Motor+Gear reducer |

Libao |

|

|

Knurling motor +Gear reducer |

Taibang |

Taiwan |

|

Bottom motor +Gear reducer |

Taibang |

Taiwan |

|

Bottom stepping motor |

Taibang |

Taiwan |

|

Lubrication Motor |

Limada |

Shanghai |

|

Touch screen |

Siemens |

Germany |

|

Relay |

Siemens |

Germany |

|

Exchange parts |

Siemens |

Germany |

|

Sensor |

Moron |

Germany |

|

Driver |

Siemens |

Germany |

|

Touch Screen |

Siemens |

Germany |

|

Ultrasonic |

EVER GREEN |

Taiwan |

|

PLC |

Siemens |

Germany |

MACHINE INTRODUCTION

FBN-HC600, a newly developed from three turn-plates old type cup machine, achieves a manufacturing speed of 60-80pcs/min. This piece of paper converting equipment provides a multi-station design and is able to make single and double PE coated beverage cups, ice cream cups, coffee cups, bubble tea cups and more. In addition to that, this integrated automatic paper container forming machine combines all these processing procedures together: paper feeding, sealing, bottom cutting, lubricating, heating, knurling, curling and collecting.Outfitted with a handle applicator, this product completes the handle cutting and sealing automatically. It will save you a lot on time and manpower.

FEATURE

A.The machine adopts open cam type structure, high precision, large out-put and long life.

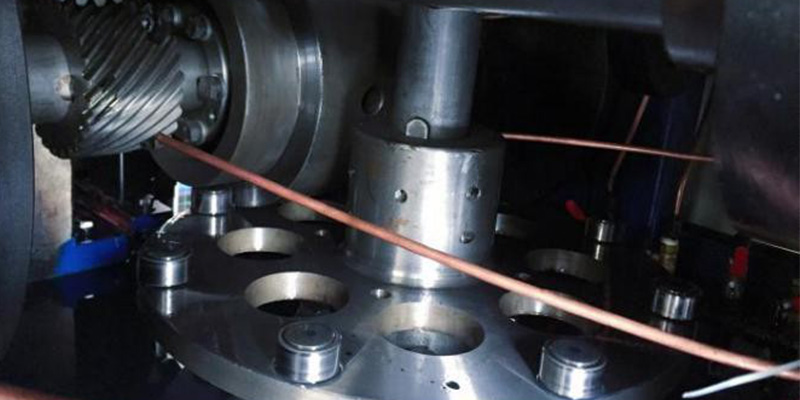

B.Longitudinal gear drive. This make up the chain drive jitter and instability's weakness.

C.Whole machine is box type structures design, filling oil by spray lubrication system So that it can run fast and stably.

D.Photoelectric failure-detecting system is available. PLC control system for the whole cup forming process.

E.Servo control to send bottom paper of cup, deliver bottom when cup tube come, otherwise no bottom delivery.

F.Stretch knife uses for bottom cutting. Easy changed and more stable.

G.Switzerland Leister heating device is equipped for cup body and bottom sealing, bottom are heated at first before they are feeding, thus improving heating effect and helping guarantee knurling.

H.The knurling device adopts hardening treatment,make up the cup knurling more beautiful and increase it use life.

HANDLE SYSTEM