Non-woven shoe cover machine: (speed: 120-160pcs/min)

Sample:

Performance and characteristics:

1.The machine use to produce non-woven material shoe cover, good quality, low price,

high output advantages, can completely replace manual shoe cover, save labor, reduce costs,

can becustomized according to customer requirements, this machine is automated.

2.Automation of the whole process from feeding raw materials to layered products to counting products.

With computer control and automatic tension control, hot hand electric welding can be debugged,

both ends of shoe sleeve and rubber band can be effectively fixed, and the whole process from

raw materials to finished products can be automated. Only one person is needed in the whole

process of operation.

3. Frequency conversion speed regulation.

4. Delivery is the finished product.

5. Automatic constant temperature control.

6. Hot hand electric welding can be debugged.

Production process:

Automatic feeding-importing-folding-connecting-cutting

Technical Data:

| Suitable material | Non-woven |

| Machine size | 1900mm*1800mm*1600mm(L*W*H) |

| Package size | 1900mm*1800mm*1600mm(L*W*H) |

| Capacity | 120-160 Pcs/min |

| voltage | 220v/380v (according to customer requirement) |

| Weight | Machine weight:750kg ;Packing weight:800kg |

| power | 3.8kw |

| Finished products size | 400*160mm(L*W) other size make according to customer requirement |

| Material Feeding | Rubber band,Non-woven |

Main configuration:

| Name | Note | Quantity | Brand |

| Edge corrector | Feeding device | 1 | China |

| Mechanical shaft | Feeding shaft | 1 | China |

| ultrasonic |

|

4 | China |

| Hemming device | Post-position | 2 | China |

| Rubber band device |

|

2 | China |

| Triangular hem |

|

1 | China |

| Traction roller |

|

1 | China |

| Strengthened ironing device |

|

1 | China |

| Side sealing device |

|

1 | China |

| cutter | Roller type | 1 | China |

| Magnetic powder controller | 2.5KG | 1 | China |

| Gear box motor | 1.5KW |

1 |

China |

| Frequency converter | Delta 1.5KW | 1 | Taiwan |

| electrical equipment | Schneider & Chint |

|

France & China |

| Body | Alu alloy |

|

China |

Machine pictures: we produce 20sets machine per month. We can deliver machine within 2days.

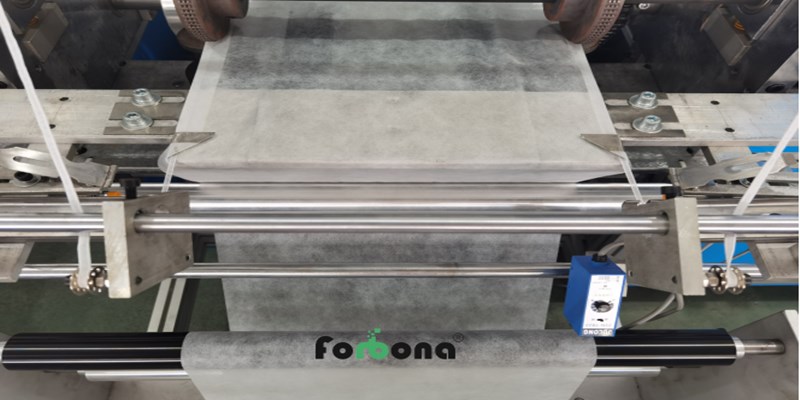

Material feeding:

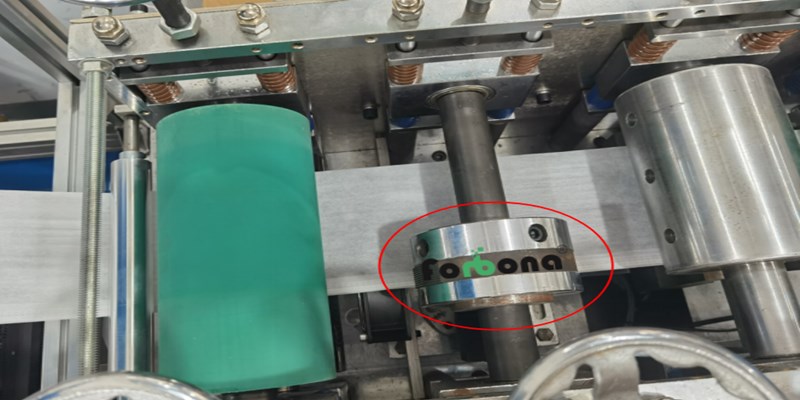

Feeding rubber band: welding by ultrasonic:

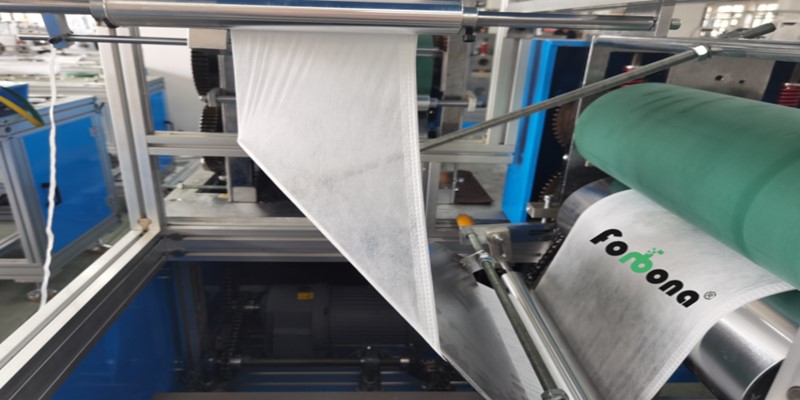

Folding the non-woven: After folded:

Side sealing by ultrasonic: Another side sealing by ultrasonic:

TATALLY FOUR SETS ULTRASONIC SET ON THE MACHINE.

Cutter:

Finished products comes out:

Control plate:easy to operate.

Our company:

Certificate: