Plastic shoe cover making machine: (speed: 130-160pcs/min)

Sample:

Performance and characteristics:

1. Disposable Plastic shoe cover making machine manufacturer, can produce PE and CPE shoe cover, good quality, low price, high output advantages, can completely replace manual shoe cover, save labor, reduce costs, can be customized according to customer requirements, this machine is automated.

2.Automation of the whole process from feeding raw materials to layered products to counting products.

From feeding raw materials to finished products, the whole process of automatic operation only needs one person.

3. Frequency conversion speed regulation.

4. Delivery is the finished product.

5. Automatic constant temperature control.

| Suitable material | PE、CPE |

| Machine size | 1500mm*1500mm*1700mm (L*W*H) |

| Package size | 1700mm*1550mm*1300mm(L*W*H) |

| Capacity | 130-160 Pcs/min |

| voltage | 220v/380v (according to customer requirement) |

| Weight | 750kg |

| power | 3.5kw |

| Finished products size | 400*160mm(L*W) other size make according to customer requirement |

| Material Feeding | Rubber band,plastic film |

Main configuration:

| Name | Note | Quantity | Brand |

| Feeding shaft | Mechannical shaft | 1 | China |

| Hemming device | Post position | 1 | China |

| Traction roll | Post position | 1 | China |

| Heating wheel |

|

2 | China |

| Rubber band device |

|

2 | China |

| Triangular hem |

|

1 | China |

| High temperature roll |

|

3 | China |

| Reducer motor | 1.5KW | 1 | China |

| Strengthened ironing device |

|

1 | China |

| Copper knife |

|

1 | China |

| Fuse device | Electric heating wire | 1 | China |

| Cutter | Roller type |

1 |

China |

| Electrostatic Eliminator | 1.6KW | 1 | China |

| Electrical equipment | Schneider |

|

France |

| Thermometer | Omron | 4 | Japan |

| Frequency converter | DELTA 1.5KW | 1 | Taiwan |

| Body | 6 size Channel steel |

|

China |

| Collector ring |

|

5 | China |

Machine pictures: we produce 20sets machine per month. We can deliver machine within 2days.

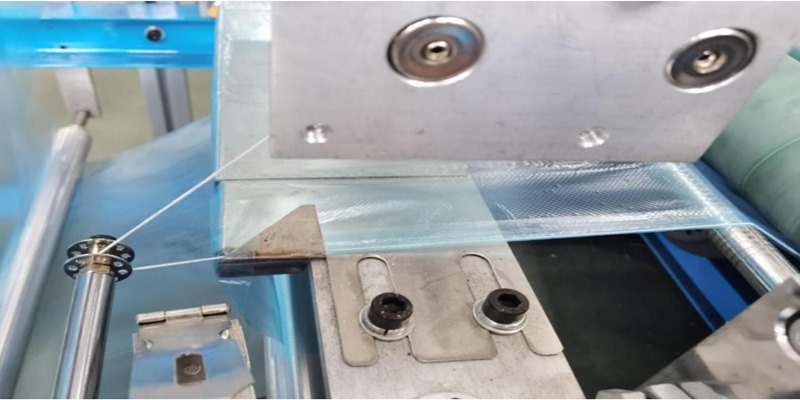

Material feeding:

Feeding rubber band: Sealing by heater:

Folding the plastic film: After folded:

Non-woven feeding and cutting system: Welding by ultrasonic:

Heating Cutter:

Finished products comes out:

Control plate:easy to operate.

Our company:

Certificate: